When it comes to electric motors, there are general-purpose models and specialized ones designed for applications like automated guided vehicles (AGVs) or autonomous mobile robots (AMRs). While standard motors work well for most automation tasks, using a motor system with built-in features can significantly speed up your design process. In this post, we’ll explore some of these key features that help optimize performance in AGV and AMR applications.

Accurate Speed Regulation Prevents Weaving

|

Speed differences between the right and left wheels can cause an AGV to weave, leading to unstable movement. With built-in speed regulation using hall-effect sensors, fluctuations are minimized, ensuring smoother operation and preventing unwanted weaving. |

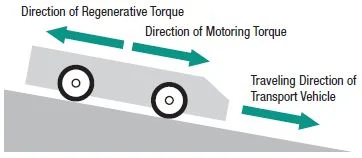

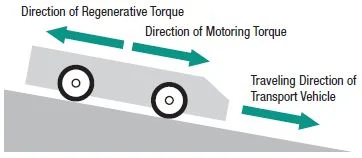

Vector Control for Ramp Operation

| In ramp operations, maintaining speed control is challenging due to gravity affecting the motor’s performance. The built-in "Vector Control" feature ensures precise torque control and load factor monitoring, allowing for tight speed regulation and effective back EMF management. |

|

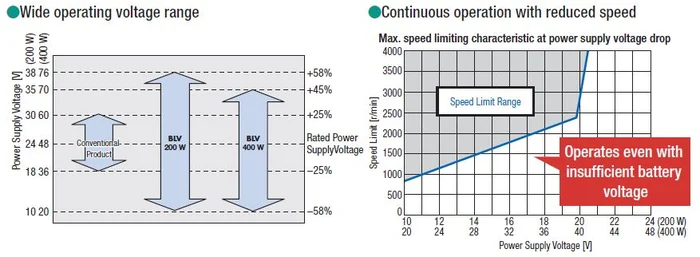

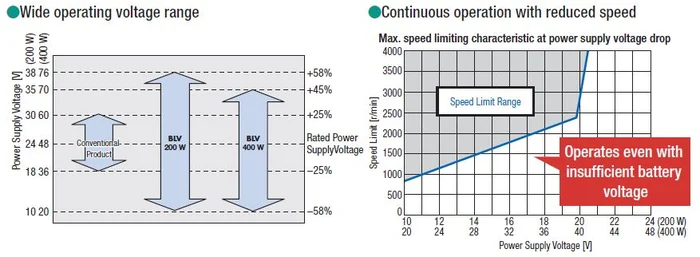

Low Battery Operation

For battery-powered vehicles, efficient use of power is essential. Motors that support low battery operation can maintain performance even as voltage drops. These systems accept a wider input voltage range and automatically limit speed based on available power. When the voltage falls below a set threshold, a warning signal is triggered, helping operators return the vehicle to a charging station.

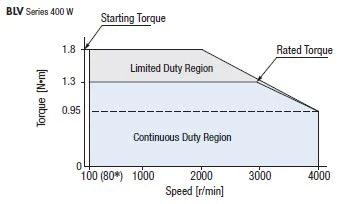

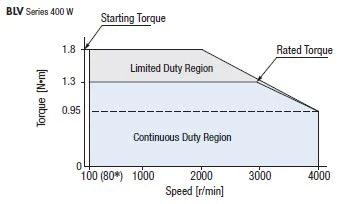

Constant Torque & Wide Speed Range

|

Built-in limits on speed and current help prevent overheating and ensure consistent performance, even under varying loads. |

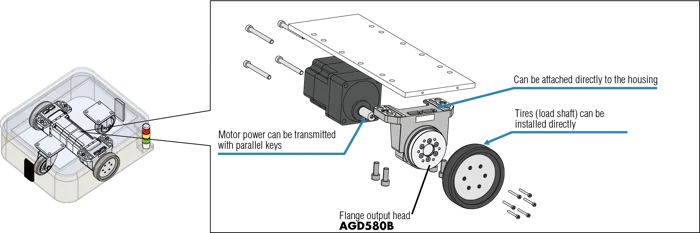

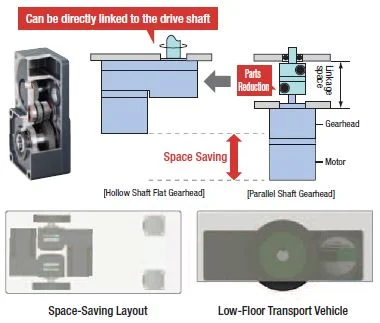

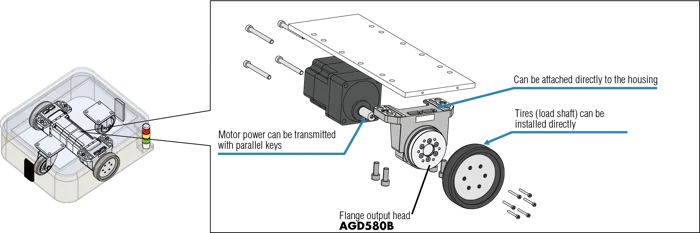

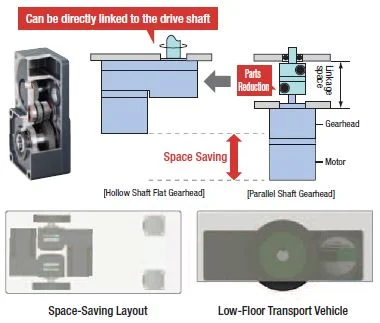

Unique Flat Hollow Shaft Gearhead Design with High Load to Motor Ratio

Here's how a parallel shaft brushless gear motor would be configured in the drivetrain of an AGV. A flange drive adapter, AGD580B, connects the gear motor shaft to the wheel or tire.

The flat-style hollow shaft gearhead allows for a compact layout, making it ideal for space-constrained designs. It can be directly connected to the wheel shaft without a coupling, reducing overall size and complexity.

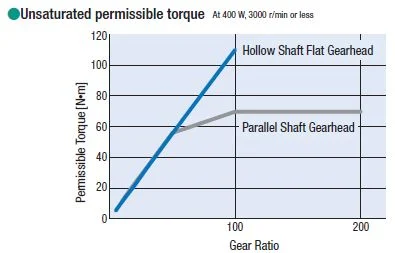

|

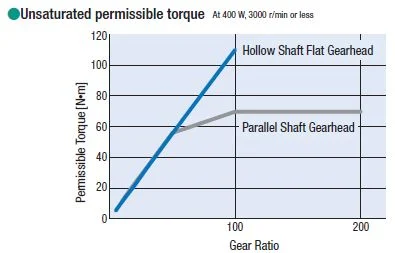

Larger gears, bearings, and a rigid case design allow the flat-style gearhead to handle high torque and radial loads efficiently. This design avoids torque saturation, enabling higher performance compared to traditional gearheads. |

|

The robust construction of the flat-style gearhead ensures high torque capacity and durability, making it ideal for heavy-duty applications. |

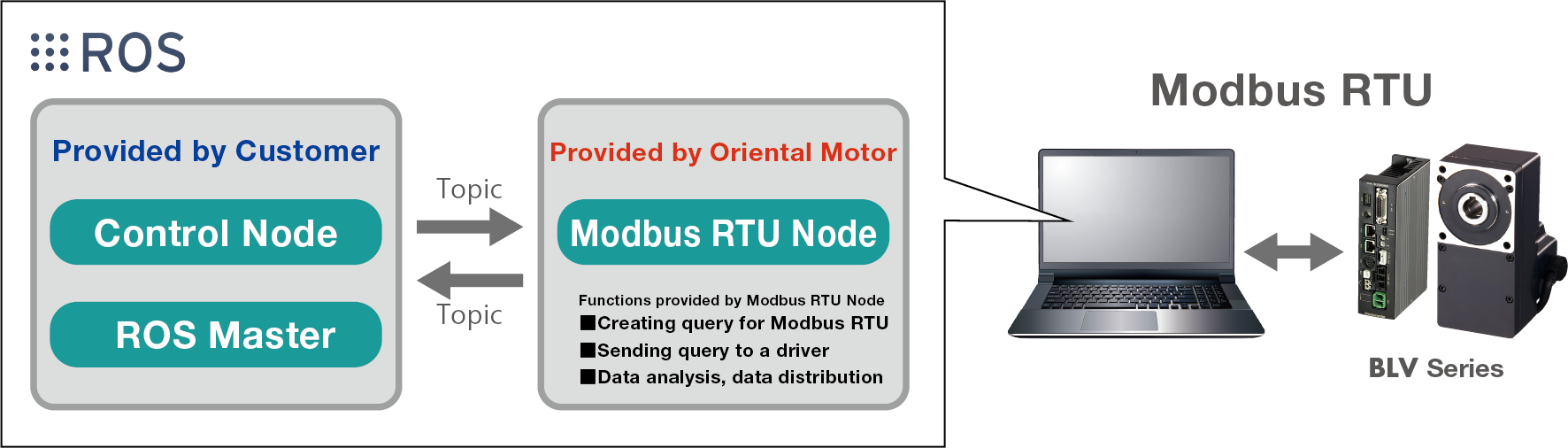

Network Capability

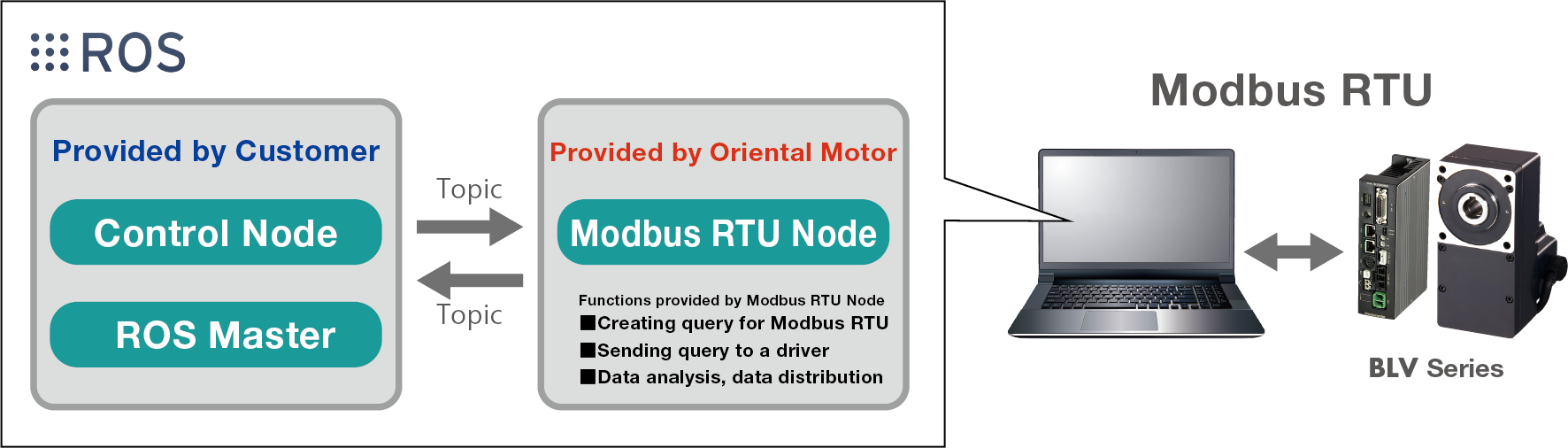

The standard built-in industrial communication protocol is Modbus RTU. For robot programming support with ROS (Robot Operating System), please comment below.

Additional protocols such as EtherNet/IP, EtherCAT, CC-Link, Mechatrolink II/III, and SSCNETIII/H are also available. CANopen is supported on the new BLV Series R Type.

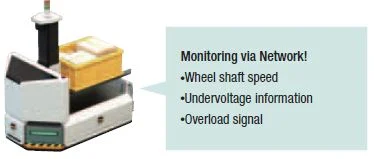

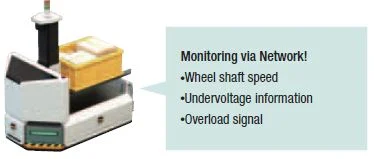

Real-time monitoring of wheel shaft speeds, load factors, and alarms from all axes can be achieved through software or network communication.

Â

| TIP: Improve stop accuracy & avoid back-driving |

|

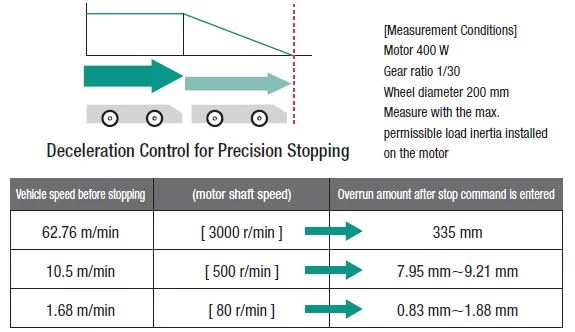

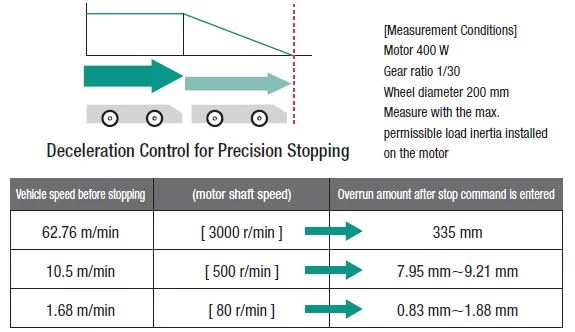

Proper deceleration control reduces overrun, improving stopping accuracy. For example, the difference in overrun between stopping at 3,000 RPM vs 80 RPM could be over 330 mm (with a 200 mm wheel diameter). |

|

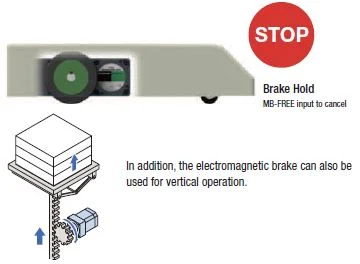

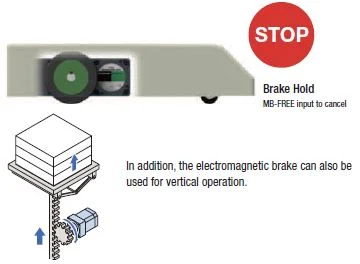

Manual back-driving an AGV or AMR may generate back EMF that could damage the power supply or drive circuits. A power-off-activated electromagnetic brake helps lock the vehicle in place during loading, recharging, or vertical operations. |

|

Â

NEW Product: BLV Series R Type

|

Oriental Motor's BLV Series R Type includes a motor and dedicated compact driver for guaranteed performance. Built-in features like torque limiting and wide battery voltage input make it ideal for battery-powered vehicles.

The BLV series R Type is available in 1/4 and 1/2 HP, with rated torque up to 970 lb-in using the FR flat-style gearhead. 60W and 400W versions will be available soon.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3c4debe8-bbbd-4b64-8e7a-63953252bb1f', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3c4debe8-bbbd-4b64-8e7a-63953252bb1f', {"useNewLoader":"true","region":"na1"});

Contact our technical support team for other product options.

|

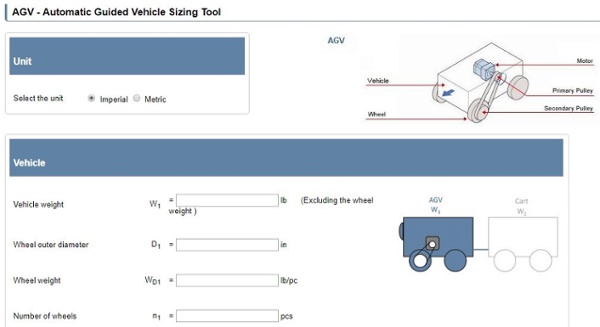

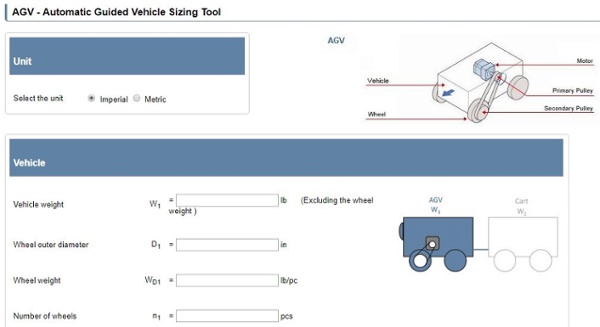

Ready to Size a Motor?

|

An undersized or oversized motor can create headaches later. Use our AGV motor sizing tool to calculate the three most important factors for motor selection: torque, speed, and moment of inertia.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '03b91476-407c-442b-a1de-f3242d9637de', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '03b91476-407c-442b-a1de-f3242d9637de', {"useNewLoader":"true","region":"na1"});

|

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '99bc0ad1-7643-424e-8b3a-ac26c7676444', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '99bc0ad1-7643-424e-8b3a-ac26c7676444', {"useNewLoader":"true","region":"na1"}); |

Â

Subscribe to receive our latest updates and insights.

Â

Hydraulic Components

There are many types of valves, such as hydraulic valves, globe valves, overflow valves, cleaning valves, gate valves, butterfly valves, ball valves, etc.

We are good at processing heat-treated valve core and valve sleeve, end cap and piston rod and other parts

The hydraulic valve is an automatic component operated with pressure oil. It is controlled by the pressure oil of the pressure distribution valve. It is usually used in combination with an electromagnetic pressure distribution valve. Commonly used in oil circuits such as clamping, control and lubrication. There are direct acting type and pilot type.

The spool is a valve part that realizes the basic functions of directional control, pressure control or flow control by means of its movement.

Shut-off valves, also known as gate valves, are forced-sealed valves, so when the valve is closed, pressure must be applied to the clapper to force the sealing surface to not leak. When the medium enters the valve from below the clapper, the resistance to be overcome by the operating force is the friction force between the stem and the packing and the thrust generated by the pressure of the medium. The diameter should be large, otherwise the failure to bend the valve stem will occur. According to the connection method, it is divided into three types: flange connection, screw connection and welding connection. After the appearance of the self-sealing valve, the medium flow direction of the shut-off valve is changed into the valve cavity from above the valve flap. At this time, under the action of the medium pressure, the force of closing the valve is small, and the force of opening the valve is large, the diameter of the valve stem can be corresponding To reduce. At the same time, under the action of the medium, this form of valve is also relatively tight. China's valve "three chemical" once stipulated that the flow direction of the globe valve should be top-down. When the cut-off valve is opened, the opening height of the valve flap is 25% to 30% of the nominal diameter. The flow rate has reached the maximum, indicating that the valve has reached the fully open position. Therefore, the fully open position of the shut-off valve should be determined by the stroke of the disc.

Hydraulic components,spools and manifolds Manufacturers

Dayue Precision Technology , https://www.dayuechn.com

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3c4debe8-bbbd-4b64-8e7a-63953252bb1f', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3c4debe8-bbbd-4b64-8e7a-63953252bb1f', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '03b91476-407c-442b-a1de-f3242d9637de', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '03b91476-407c-442b-a1de-f3242d9637de', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '99bc0ad1-7643-424e-8b3a-ac26c7676444', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '99bc0ad1-7643-424e-8b3a-ac26c7676444', {"useNewLoader":"true","region":"na1"});