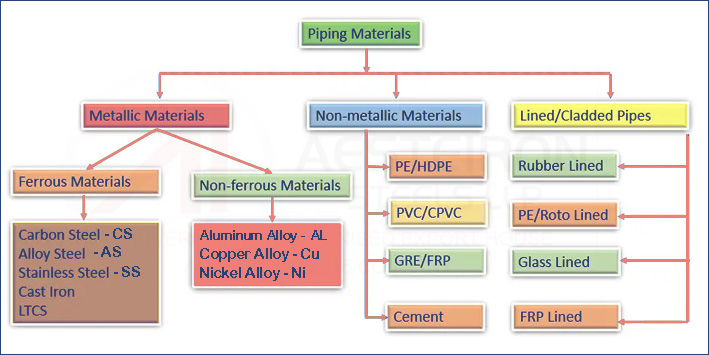

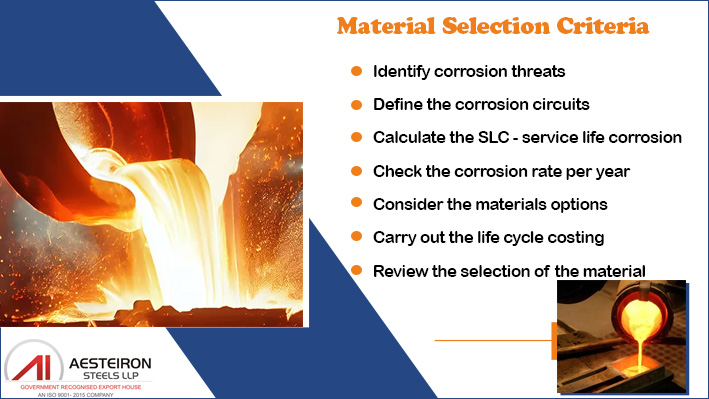

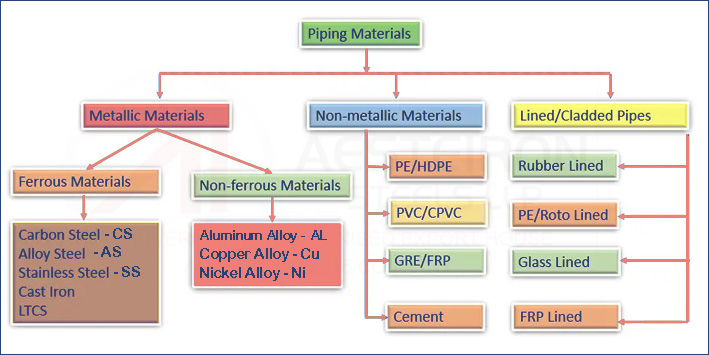

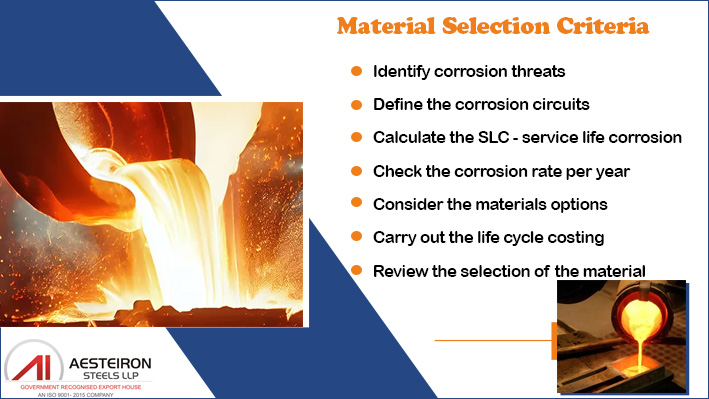

Choosing the right piping material is a critical decision that involves evaluating various factors, such as environmental conditions, pressure requirements, and chemical compatibility. Manufacturers must carefully assess the strengths and weaknesses of each material to ensure optimal performance and longevity of the piping system. Every type of piping material has its own set of advantages and limitations, and the selection directly impacts the overall success and efficiency of the system.

To extend the lifespan of piping materials, regular inspection and maintenance are essential. This helps in identifying early signs of wear, corrosion, or structural issues before they lead to costly failures or safety hazards.

Table of contents

- 25 Types of Piping Material Used in Oil and Gas Industry

- Stainless Steel Function in Corrosive Environments

- Pros and Cons of Carbon Steel

- Pros and Cons of Alloy Steel

- Application of HDPE Pipe

- Duplex and Super Duplex Advantages and Disadvantages

- Benefits of Using Nickel Alloy Material in Oil and Gas Applications

- Fiberglass and Polyvinylidene Fluoride Material Uses in Oil and Gas Application

- Corrosion Agents in Oil & Gas

- Corrosion Threats in Oil & Gas Applications

- Piping Material Inspection Checklist

- Pros and Cons of Copper, Brass, Galvanized Steel, PVC, Aluminum Material

- Mechanical Properties of Pipe Materials

- Metallic Piping Materials Effects of Alloying Elements

- Typical Pipe Material Selection Criteria

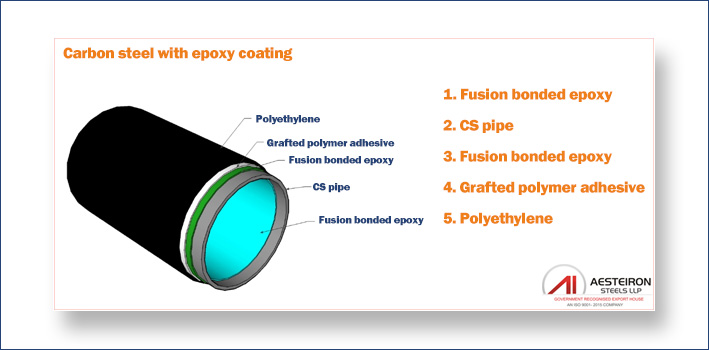

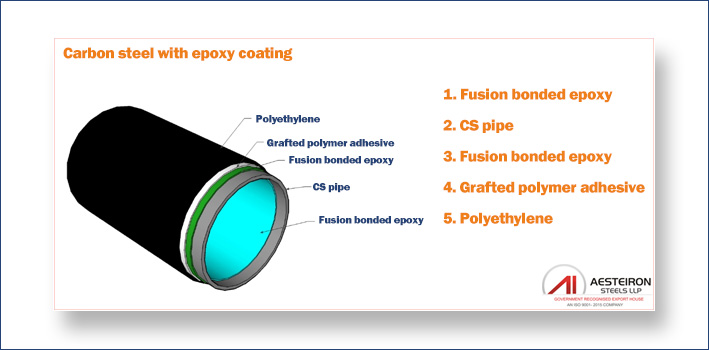

- Carbon Steel With Epoxy Coating

- Material Service Checks

- Copper Nickel Advantages

Steel pipes are widely used in oil and gas industries for transporting gas and liquids

In the oil and gas industry, steel pipes are commonly used due to their durability, strength, and versatility. While different types of steel pipes offer varying properties, each has unique characteristics that make it suitable for specific applications. The following list outlines some of the most commonly used steel pipe materials in this sector.

25 Types of Piping Material Used in Oil and Gas Industry

| Material |

Grades |

| Carbon Steel |

|

| Alloy Steel |

|

| Stainless Steel |

|

| Duplex Stainless Steel |

|

| Nickel-Alloy Steel |

|

| Super Duplex Stainless Steel |

|

| Titanium |

|

| Hastelloy |

|

| Monel |

|

| PVC |

– |

| CPVC |

|

| Silicon Bronze |

|

| HDPE |

– |

| PEX |

– |

| Stainless Steel with Internal Lining |

Various linings |

| Fiberglass |

FRP |

| Carbon Steel with CRA Lining |

Various CRA materials |

| High-Performance Alloys |

Various specialty alloys |

| Concrete-Lined Steel Pipe |

– |

| Copper |

– |

| Brass |

|

| Aluminum |

|

| Zirconium |

|

| Alloy 20 |

– |

| Lead |

– |

SS pipes are widely used in petroleum industry due to their corrosion resistance property

Stainless steel pipes are known for their ability to resist corrosion, making them ideal for use in the petroleum industry. These pipes contain at least 10.5% chromium, which reacts with oxygen in the air to form a protective layer that prevents rust and degradation. This makes stainless steel an excellent choice for environments where exposure to harsh chemicals and weather is common.

Stainless Steel Function in Corrosive Environments

| Type of Stainless Steel |

Grades |

Corrosion Resistance |

| Austenitic |

304, 304L, 316, 316L, 317, 321, 347 |

High resistance to general corrosion and chloride situations |

| Duplex |

2205 |

Superior tensile strength and stress corrosion breaking resistance |

| Super Duplex |

2507 |

Exceptionally strong and resistant to corrosion |

| Martensitic |

410, 420 |

Greater hardness and less resistance to corrosion |

Most common types of piping material are carbon steel and alloy steel

The table below outlines the key pros and cons of carbon steel and alloy steel, helping you understand their suitability for different applications. This information can guide your decision-making process when selecting the best piping material for your needs.

Pros and Cons of Carbon Steel

| Pros |

Cons |

| Cost-effective |

Susceptible to corrosion |

| Good strength and durability |

Need protective coatings or cathodic protection |

Pros and Cons of Alloy Steel

| Pros |

Cons |

| High strength and toughness |

More expensive |

| Suitable for high-stress applications |

Need careful handling and welding |

| Good resistance to high temp. and pressure |

|

HDPE pipe is widely used to transfer fluids and gases

High-density polyethylene (HDPE) pipes are flexible plastic pipes commonly used to transport fluids and gases. They are made from high-density polyethylene, offering strong molecular bonding that makes them suitable for high-pressure pipeline systems. HDPE is resistant to various environmental conditions and is often chosen when cost-effective yet durable piping is needed.

HDPE pipes are used in a wide range of applications, including pipeline transportation, chemical handling, underground installations, offshore operations, drilling, and more. Their versatility makes them a popular choice in many industries.

Application of HDPE Pipe

- Pipeline Transportation

- Chemical Handling

- Underground Installations

- Offshore

- Drilling & Exploration

- Water Injection

- Environmental Protection

- Infrastructure

In the offshore industry mainly duplex and super duplex piping are used

Duplex and super duplex piping materials are widely used in offshore applications due to their exceptional strength, high corrosion resistance, and durability in harsh environments. These materials are particularly effective because of their higher content of chromium, molybdenum, and nitrogen, which contribute to their superior mechanical and corrosion-resistant properties.

Duplex and Super Duplex Advantages and Disadvantages

| Material |

Pros |

Cons |

| Duplex |

High Strength |

Lower Corrosion Resistance |

| Corrosion Resistance |

Limited Temp. Range |

| Cost-Effectiveness |

Potential for Sensitization |

| Good Weldability |

Thermal Sensitivity |

| Super Duplex |

Superior Strength |

Expensive |

| Enhanced Corrosion Resistance |

Limited Weldability |

| High Resistance to Erosion and Abrasion |

Thermal Sensitivity |

| Cost Efficiency |

Potential for Sensitization |

Benefits of Using Nickel Alloy Material in Oil and Gas Applications

- Corrosion Resistance

- High-Temperature Performance

- Wear and Erosion Resistance

- Mechanical Properties

- Hydrogen Sulfide Resistance

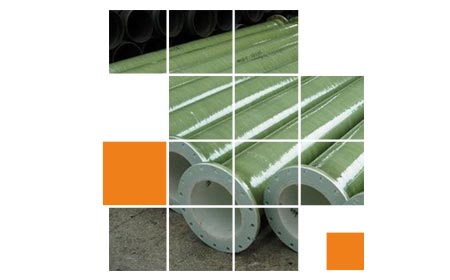

Fiberglass and Polyvinylidene Fluoride Material Uses in Oil and Gas Application

Fiberglass Application

- Offshore

- Seawater

- Hydrocarbon Transport

- Cooling Water Systems

- Chemical Handling Systems

- Tank Linings

- Ventilation and Drainage Systems

Polyvinylidene Fluoride Application

- Chemical Injection

- Acid and Alkali Transport

- Refining Processes

- Seawater Systems

- Used in high-purity fluid

- Cooling Systems used where chemical resistance is crucial

Corrosion Agents in Oil & Gas

- Carbon Dioxide

- Oxygen

- Hydrogen Sulphide

- Water

- Chlorides

Corrosion Threats in Oil & Gas Applications

- Sweet Corrosion – CO2 Corrosion

- Sour Corrosion – H2S Corrosion

- Corrosion due to Oxygen

- Chlorides and Bicarbonates

- Erosion Corrosion

- Microbiologically

- Corrosion Under Insulation

- External Atmospheric Corrosion

Piping Material Inspection Checklist

- Visual Inspection

- Dimensional Check

- Material Certification

- Weld Inspection

- Corrosion and Coating Inspection

- Pressure Rating and Testing

- Documentation and Compliance

Pros and Cons of Copper, Brass, Galvanized Steel, PVC, Aluminum Material

| Pipe Material |

Pros |

Cons |

| Copper |

- Durable and longlasting

- Corrosion resistance

- Flexible

- Recyclable

|

- Expensive

- High thermal conductivity

|

| Galvanized Steel |

- Strong and durable

- Corrosion resistant due to zinc coating

- Long service life

|

- Higher cost

- Difficult to handle

- Can rust over time

|

| Brass |

- Corrosion resistant

- Strong and durable

- Easy to machine

|

- Expensive

- Can become brittle over time

|

| PVC |

- Easy to install

- Cost-effective

- Low maintenance

|

- Not suitable for high temperature applications

- Environmental impact of production

|

| Aluminum |

- Naturally corrosion resistant

- Lightweight

- Easy to install

|

- Scratching and denting

- Can be costly

|

Mechanical Properties of Pipe Materials

- Modulus of Elasticity: Stress to strain ratio measured using tension tests

- Plastic range

- Elastic range

- Yield Strength

- Ultimate Tensile Strength

- Hardness: Tested by Brinell or Rockwell

- Ductility

- Fatigue Resistance

- Toughness

Metallic Piping Materials Effects of Alloying Elements

| Alloying Element |

Effect |

| Carbon |

|

- Increases hardness, wear resistance and strength

- Reduces ductility

|

| Chromium |

|

- Enhances oxidation and corrosion resistance, hardness, toughness and strength

|

| Molybdenum |

|

- Increases strength and hardness at high temperatures

|

| Manganese |

|

- Increases strength, wear resistance, toughness and ductility and hardness

|

| Silicon |

|

- Increases strength, oxidation resistance and hardness

|

| Copper |

|

- Increases strength and resistance to stress corrosion cracking

|

| Tungsten |

|

- Improves hardness and wear resistance and strength at high temperatures

|

Typical Pipe Material Selection Criteria

Nickel 200/201

- Good mechanical properties

- Excellent corrosive resistance

- Good ductility at low temp

- Excellent weldability

Monel 400/500

- Good resistance to acidic conditions

- Ni-Cu Alloy

- Good ductility at low temp

- UNS 04400 – up to 550°C

- UNS 05500 – up to 650°C

Inconel Selection

| Inconel 600/601 |

Inconel 625 |

Inconel 825 |

Inconel 800 |

Inconel 800H |

| Ni-Cr-Fe |

Ni-Cr-Mo-Fe |

Ni-Cr-Mo-Fe |

Ni-Cr-Fe |

Ni-Cr-Fe |

| Excellent oxidation |

Excellent strength |

High resistance to seawater, phosphoric and sulfuric acid |

– |

– |

| Excellent corrosive resistance |

Good ductility |

Good corrosion resistance |

– |

– |

| Weldability |

Better weldability |

used in condenser and heat exchanger |

– |

– |

Hastelloy Selection

- Suitable for extremely corrosive conditions

- Best for strong acids, seawater, formate acids and saline solutions

- Good for oxidizing applications

- Corrosion resistant to wet hydrochloride solutions

Titanium – B861 / B862

- About 6% Nitrogen

- Excellent erosion resistance

- High strength

- Good formability, toughness and weldability

- Zero corrosion allowance

Carbon Steel With Epoxy Coating

Material Service Checks

| Caustic |

- Need to check NaOH or KOH concentration

- Require CS and PWHT material

|

| Amine |

- Services – MEA, DIPA, DEA, DGA

- Fluid velocity : < 2 m/sec for CS

- SS for high temps and velocity

|

| Oxygen |

- Carbon, stainless and monel material used

- Try to avoid threaded piping

- Cleanliness required

|

| Wet H2S |

- In water : > wt% 50 to 75 ppm

- Hardness : 200 BHN

|

| Ammonia |

- Cryogenic material used for gaseous service

- carbon steel temp. must be > -29°C

|

| Hydrogen |

- Carbon steel used up to 232°C

- SS used up to 330° to 400°C

- Inconel 800 used up to 400°C

|

| Chlorine |

- Carbon steel is used in liquid chlorine

- PWHT is not required

|

| Hydrofluoric Acid |

- Concentration > 1ppm

- hardness up to 200 BHN

|

Copper Nickel Advantages

- Excellent seawater corrosion resistance

- Long service life

- Better hydraulic performance

Glass Bottle

We are Professional Glass Bottle manufacturer is located in China, including Glass Dropper Bottle,Essential Oil Glass Bottle

There are many different volumes ,10ml 20ml 30ml 40ml 50ml 60ml 80ml 100ml 120ml 150ml 200ml etc.

Can paint to any color and print any Logo.

Used for Essential Oil and other cosmetic packaging.

.

Glass Bottle,Glass Dropper Bottle,Amber Essential Oil Glass Bottle,Cosmetics Glass Bottle

NINGBO CRETE PLASTIC CO.,LTD , https://www.crete-sprayer.com