For Independent Power Producers (IPPs) that acquire solar assets after the project has been developed and designed—rather than during the development or design phases—there are fewer opportunities to address design issues or implement value engineering. However, it remains crucial to involve an Owner’s Engineer (OE) or Independent Engineer (IE) as early as possible in the process to ensure safety, quality, and long-term operational performance.

In the first part of this two-part article, I outlined strategies for maximizing the value of third-party engineering services throughout project development and pre-construction. In this second part, I will focus on the specific value-added engineering services that Pure Power offers to IPPs during and after construction.

**IE or OE Engaged During Construction**

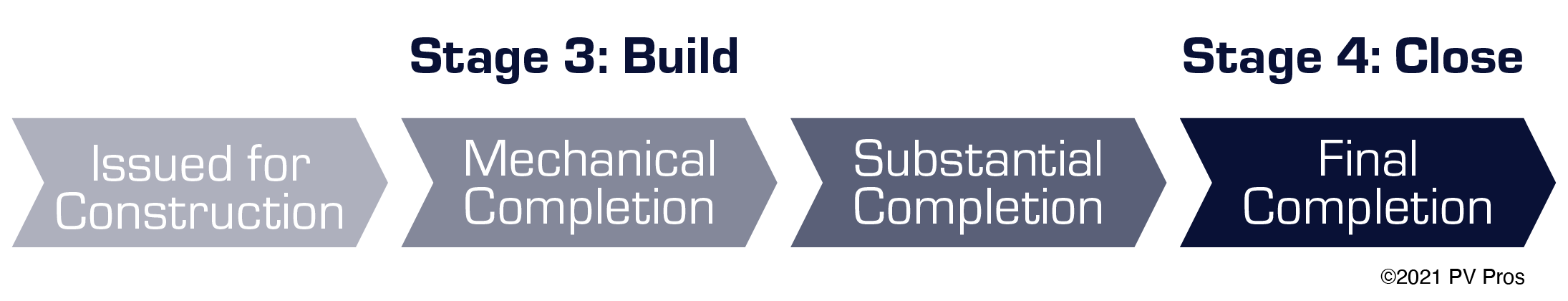

The key milestone that separates pre-construction from actual construction is when the engineer of record releases the "issued for construction" (IFC) drawing set. Once construction begins, the primary objective of independent and owner's engineering services is to verify that the delivered project aligns with the original design and specifications.

The earlier Pure Power is engaged as an OE or IE, the more value we can add. It is in everyone’s best interest for these quality assurance and quality control (QA/QC) checks to begin right from the start of construction. Addressing a problem in the early stages—such as a “golden rowâ€â€”is far easier and less costly than fixing it after months of production.

**Quality Assurance and Quality Control**

Verifying as-built conditions against the IFC drawings and project specifications is a core part of QA/QC activities. This includes visual inspections, insulation resistance tests, very-low-frequency (VLF) testing, polarity and open-circuit voltage checks, and ground continuity tests. These steps are essential before system energization and commissioning.

During commissioning, all power equipment—including inverters, protection devices, transformers, and reclosers—is tested against the latest planset, energized, and operated. These tests follow manufacturer-approved standards, such as those from the InterNational Electrical Testing Association (NETA) or the International Electrotechnical Commission (IEC), including **IEC 62446-1**, which outlines requirements for testing, documentation, and maintenance of photovoltaic (PV) systems.

**Milestone Verification**

Major project milestones like mechanical completion and substantial completion often trigger significant progress payments. Lenders frequently engage Pure Power during construction to provide independently verified milestone reports. As an OE, we also offer site visits to help owners monitor progress. Once funds are released, the project owner or lender loses leverage to correct any deficiencies or bring the project into compliance.

**Performance Validation**

As discussed in a previous post, capacity and performance ratio tests are conducted based on detailed industry standards. When done correctly, these tests confirm that the solar asset is performing as expected. These validations are critical for de-risking solar asset acquisitions, whether the project is newly built or already operational.

**IE or OE Engaged During Post-Construction**

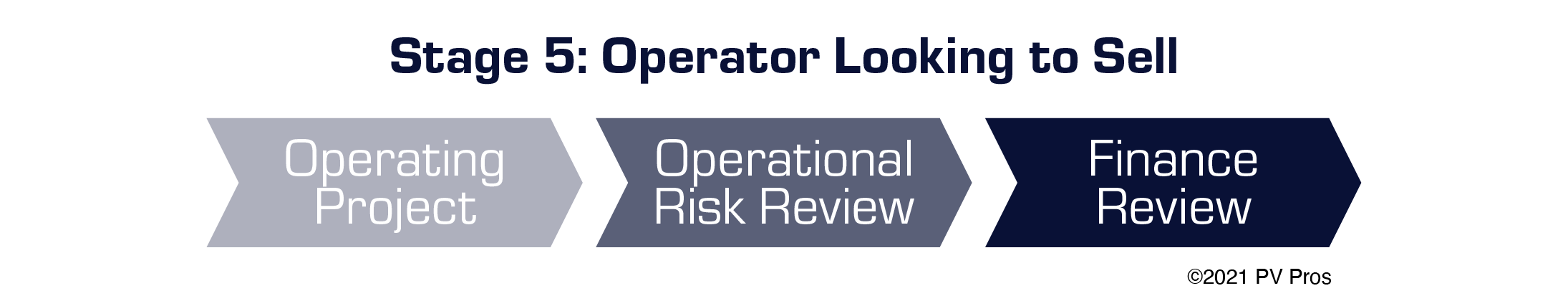

For IPPs that specialize in acquiring operational assets, technical due diligence must include a thorough assessment of the as-built conditions. This applies to both new and older systems. After construction ends and commercial operations begin, it's just as important to validate the PVsyst model as it is to evaluate the fielded design and construction.

Ideally, the operating system should be free from defects and safety hazards. A well-documented and properly maintained system reduces future risks and costs.

**As-Built Drawing Review**

As I've mentioned before, if the record drawings don't match the actual installed system, it can lead to unnecessary and avoidable costs. This review is a vital step in any asset acquisition. The goal is to ensure that the fielded system matches the documented one.

**Performance Analysis**

Since all revenue from a solar asset is tied to the PVsyst model, it’s essential to verify its accuracy and make necessary adjustments to reflect real-world performance. This is especially important when acquiring assets that have been in operation for some time. Older systems may require different derate factors for soiling, degradation, and availability compared to new installations. Additionally, Pure Power can enhance model accuracy by accounting for environmental changes, such as tree growth, and using updated modeling software.

**Safety Evaluation**

After construction is complete, a key goal of technical due diligence—such as plan reviews, QA/QC checks, and field inspections—is to confirm that the solar asset is free from safety hazards. Once an acquisition is finalized, any required modifications or repairs will come at a cost to the new owner. For older systems, ensuring that maintenance has been properly scheduled and executed is crucial to preventing catastrophic failures due to gradual equipment degradation.

VCV Metering Valve

Guangdong Heidler Technology Co., Ltd , https://www.hyhemit.com