Autodesk Shotgun Introduces the Future of Production Management

Â

Generative Scheduling is coming to Shotgun Software

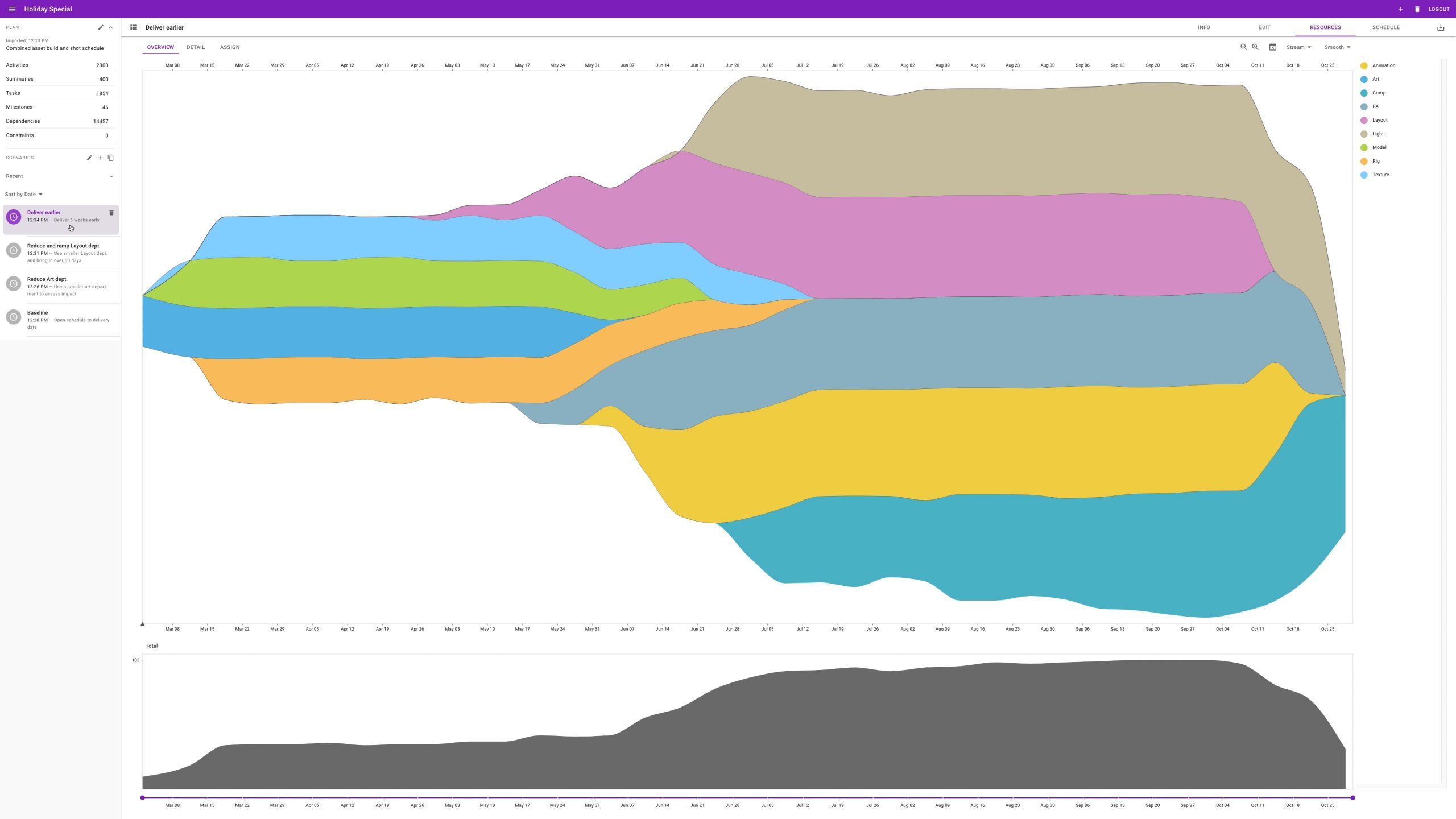

In today’s fast-paced production environment, new challenges are emerging due to a more global marketplace, evolving on-set safety protocols, and the rise of cloud-based workflows. To meet these demands, Shotgun Software is introducing machine learning-powered generative scheduling, built upon the acquisition of Consilium technology. This innovation aims to revolutionize how producers plan, schedule, and manage resources with greater accuracy, speed, and adaptability.

Shotgun has always supported open standards, which have been instrumental in creating integrated editorial and VFX workflows that allow for real-time review of visual effects within the latest edit of a scene. Additionally, asset lifecycle management is now in development, leveraging Autodesk's Forge platform to enable seamless sharing of assets and dependencies across teams and studios.

Generative Scheduling

Shotgun is bringing the power of machine learning into production management through its new generative scheduling feature, currently in early testing. For producers and production managers, this tool will transform the traditionally complex task of scheduling and resource planning into a more dynamic, predictive, and controllable process. It allows for faster, more accurate planning, helping teams stay agile and focused on delivering high-quality work.

At LAIKA, a stop-motion animation studio based in Portland, OR, the process of making a film involves thousands of sets, props, puppets, and costumes. Coordinating all this work across multiple teams is a massive challenge, and scheduling plays a crucial role in keeping everything on track.

“The first time we successfully generated a schedule using Consilium and fed it back into Shotgun was a real breakthrough. Instead of manually balancing 12,000 tasks, we could just hit a button and get a complete schedule returned in seconds. With this functionality now built directly into Shotgun, I believe even greater efficiencies are on the horizon,†said Michael Nowakowski, Pipeline Technical Director at LAIKA.

Story-in-Context

By embracing open standards, Shotgun is enhancing its editorial timeline support, bridging the communication gap between VFX and editing teams. This means artists can access and review their work in the context of the most recent edit, ensuring creative decisions are always informed by the current state of the cut.

Leveraging open standards, enhanced editorial timeline support is coming to Shotgun

Autodesk has long been a champion of open standards, which have helped unlock scalability, automation, and collaboration across the industry. These standards have enabled companies like X2X to develop tools that integrate on-set and editorial data directly into Shotgun from Adobe Premiere Pro. A custom plug-in was created for the production of *Terminator: Dark Fate*, and future updates will bring even more robust timeline integration to Shotgun.

“When you're dealing with hundreds of shot versions per day, being able to select them all, hit execute, and have them automatically placed into the timeline is a game-changer. It speeds up the review process for directors and executives, and helps us relay feedback to VFX vendors much faster. I used to spend hours cutting shots, but now I can do it in minutes,†said Jon Carr, VFX Editor on *Terminator: Dark Fate*.

Asset Lifecycle Management

The Shotgun engineering team is investing heavily in developing full-featured, open-standard-based asset management for the cloud. This will allow studios to manage and share assets throughout the entire project lifecycle, making collaboration easier and more efficient. By integrating these features into Autodesk’s Forge platform, Shotgun is helping studios transition to cloud-based workflows with confidence.

New tech in Shotgun will allow studios to share and manage assets across teams and studios in the cloud

The entertainment industry is constantly evolving, and Shotgun’s new features—generative scheduling, story-in-context, and asset lifecycle management—are setting the stage for the future of production management. To learn more about these innovations, visit www.shotgunsoftware.com.

Â

Thermoplastic Polyurethane (TPU) is a type of polymer resin that is known for its flexibility, durability, and versatility. It is a thermoplastic material, which means it can be melted and reprocessed multiple times without losing its original properties.

TPU is commonly used in various industries, including automotive, electronics, footwear, and sportswear. It is often used to make products such as phone cases, cables, hoses, seals, gaskets, and inflatable structures.

Some key properties of TPU include:

1. Flexibility: TPU has excellent flexibility, allowing it to bend and stretch without breaking. This makes it suitable for applications where flexibility is required, such as in shoe soles or flexible electronic components.

2. Abrasion resistance: TPU has good resistance to abrasion, making it suitable for applications that require durability and resistance to wear and tear.

3. Chemical resistance: TPU is resistant to many chemicals, including oils, solvents, and greases. This makes it suitable for applications where exposure to chemicals is expected.

4. Weather resistance: TPU has good weather resistance, meaning it can withstand exposure to sunlight, moisture, and extreme temperatures without degrading or losing its properties.

5. Adhesion: TPU has good adhesion to various substrates, allowing it to be easily bonded or laminated with other materials.

Overall, TPU is a versatile material that offers a balance of flexibility, durability, and chemical resistance, making it suitable for a wide range of applications.

Tpu For Tube And Hose,Food Grade Tpu Tube,Flexible Stpu Tube And Hose,Fda Grade Tpu Material

XUCHUAN CHEMICAL(SUZHOU) CO., LTD , https://www.xuchuanchem.com